Introduction

In an era where global supply chains are paramount, understanding quality control in China has never been more essential. As one of the world’s largest manufacturing hubs, China faces unique challenges and opportunities in ensuring product quality. The question often arises: Does China have quality control? The answer is a resounding yes, but it comes with layers of complexity that need to be unraveled.

Understanding Quality Control in China

Quality control in China encompasses a wide range of practices aimed at maintaining high standards throughout the manufacturing process. Various regulations and industry standards dictate how products are inspected and tested, leading to a diverse landscape of quality assurance measures. With the existence of multiple inspection companies in China, businesses can leverage these services to ensure compliance with both local and international quality standards.

The Importance of Quality Assurance

Quality assurance is not merely a checkbox on a production list; it’s integral to maintaining brand reputation and customer satisfaction. With rising consumer expectations, manufacturers must navigate the intricacies of what are the quality standards in China to avoid costly mistakes. In this context, one might wonder: What are the 4 types of Quality Control? These include process control, acceptance sampling, statistical process control, and continuous improvement—all vital for ensuring that products meet market demands.

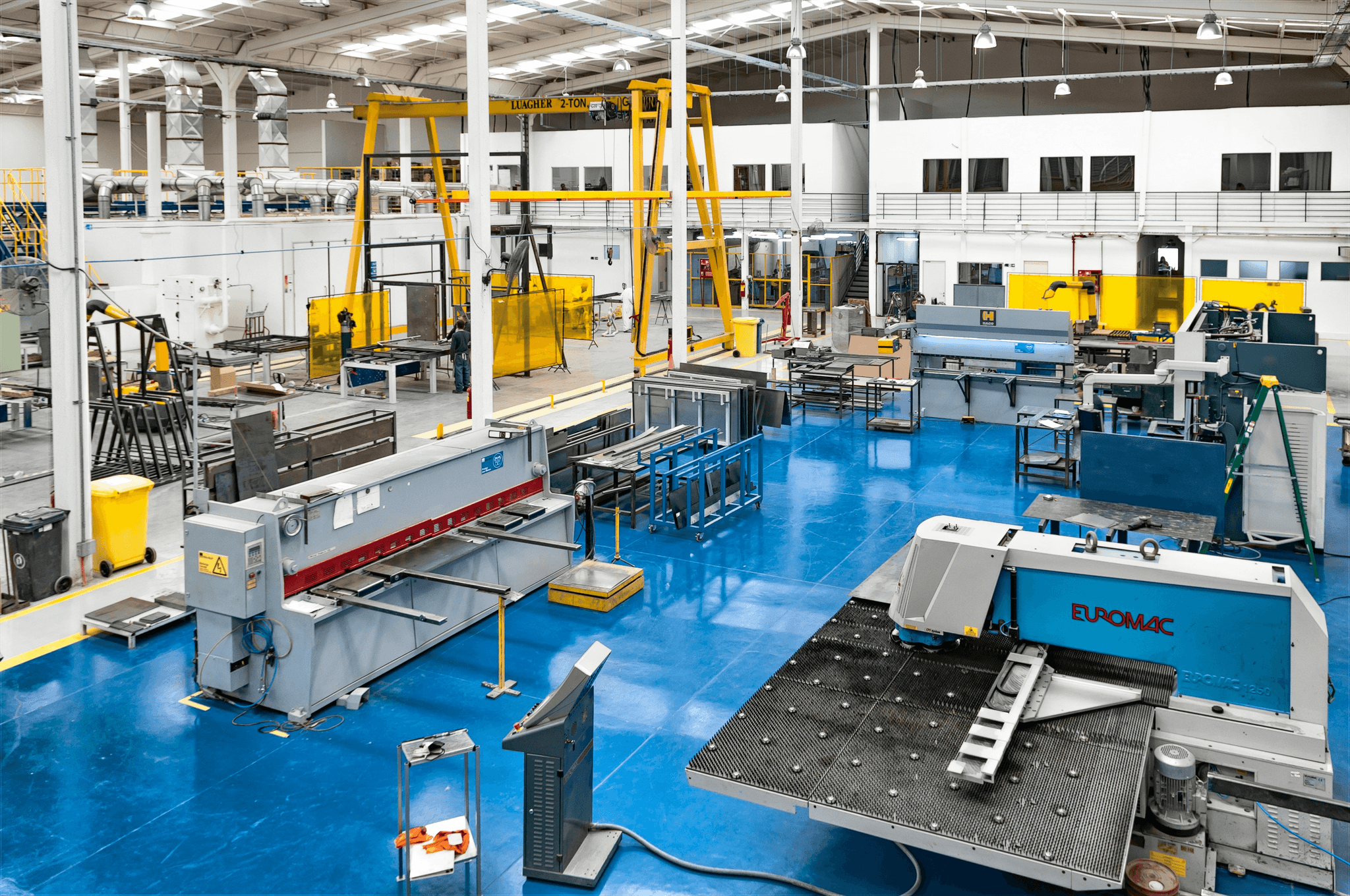

Current Landscape of Manufacturing

The current landscape of manufacturing in China is characterized by rapid growth coupled with increasing scrutiny over product quality. While many consumers question whether Does China have good quality? it’s crucial to recognize that significant strides have been made toward enhancing production processes and standards. However, challenges remain as companies strive to balance cost efficiency with stringent quality control measures—an ongoing dance that shapes the future trajectory of Chinese manufacturing.

Regulatory Challenges in Quality Control

Quality control in China is a multifaceted issue, deeply intertwined with the country's regulatory environment. Navigating these regulations can feel like a maze, especially for foreign businesses trying to ensure compliance while maintaining high standards. Does China have quality control? Absolutely, but understanding the nuances of its regulatory framework is crucial for effective quality assurance.

Navigating Chinese Regulations

Navigating Chinese regulations can be daunting, given their complexity and frequent updates. Businesses must familiarize themselves with laws that govern manufacturing practices, product safety, and environmental standards. Moreover, understanding what are the quality standards in China is essential; they often differ significantly from international norms, which can lead to confusion and compliance challenges.

The challenge doesn't end there—companies also need to account for local variations in regulations across different provinces and municipalities. This patchwork of rules means that what works in one area might not apply in another, complicating quality control efforts further. To effectively manage these complexities, many companies turn to inspection companies in China that specialize in ensuring compliance with local laws and standards.

International Standards Compliance

For manufacturers operating internationally or aiming for global markets, adherence to international standards is non-negotiable. But does China have good quality? The answer lies not just in internal regulations but also in how well Chinese firms align with global benchmarks such as ISO certifications or industry-specific guidelines. Understanding the four types of quality control—process control, acceptance sampling, continuous improvement, and total quality management—can help businesses assess their practices against these international standards.

Compliance with international norms not only enhances credibility but also opens doors to new markets where stringent quality expectations prevail. Companies must invest time and resources into aligning their operations with these standards while navigating the unique regulatory landscape of China simultaneously. This dual focus on local regulations and international compliance ensures that products meet diverse market demands without compromising on quality.

Impact of Policy Changes

Policy changes can significantly impact how businesses approach quality control in China. Recent shifts towards stricter environmental regulations or enhanced consumer protection laws mean that manufacturers must adapt quickly or face penalties that could jeopardize their operations. This fluid policy environment raises questions about stability: does it foster better quality control practices or create additional hurdles?

Moreover, staying informed about policy changes is vital for companies seeking to maintain high-quality outputs amidst evolving legal landscapes. As manufacturers adjust their strategies accordingly, they may find it beneficial to partner with inspection companies in China that keep them updated on relevant changes affecting product safety and compliance requirements. Ultimately, proactive engagement with both regulatory bodies and industry experts will empower businesses to navigate these challenges effectively while ensuring robust quality assurance processes.

Supply Chain Complexities

Navigating the intricate web of supply chains in China is no small feat, particularly when it comes to quality control in China. The diverse landscape of suppliers can create both opportunities and challenges for businesses aiming to maintain high standards. With multiple players involved, ensuring consistent quality across the board becomes a critical task that requires diligent oversight.

Managing Diverse Suppliers

When dealing with numerous suppliers, managing quality control in China can feel like herding cats—each with its own quirks and standards. Does China have quality control measures that are effective? Absolutely, but the real challenge lies in aligning these measures across various suppliers who may interpret standards differently. To tackle this, companies often turn to inspection companies in China that specialize in evaluating supplier performance and product quality before shipment.

Understanding what are the quality standards in China is essential for any business looking to thrive here. This means familiarizing yourself with local regulations and international compliance requirements while also establishing clear communication channels with your suppliers. In doing so, you not only streamline your operations but also foster better relationships built on trust and accountability.

Quality Control Across Borders

Quality control across borders adds another layer of complexity to an already intricate system. When products cross international lines, they must meet varying standards set by different countries—this raises the question: What are the 4 types of quality control? They include process control, acceptance sampling, statistical process control (SPC), and continuous improvement strategies—all vital tools for maintaining consistency despite geographical differences.

The reality is that while many manufacturers in China strive for excellence, discrepancies can arise due to cultural perceptions of quality. Does China have good quality? It certainly does—but it’s essential for businesses to actively engage with their overseas partners to ensure everyone is on the same page regarding expectations and benchmarks. By implementing robust training programs and regular audits through reliable inspection companies in China, companies can mitigate risks associated with cross-border production.

Risks in Logistics and Transportation

Logistics and transportation pose significant risks that can undermine even the best-laid plans for maintaining quality control in China. Delays or mishandling during transit can lead directly to compromised product integrity—an outcome no one wants on their watch! Businesses must be aware of potential pitfalls such as customs clearance issues or unexpected tariffs which could affect overall product quality upon arrival.

Furthermore, understanding how logistics impact what are the quality standards in China allows companies to make informed decisions about their supply chain strategies. Employing real-time tracking technologies ensures transparency throughout the shipping process; this way, any discrepancies can be addressed promptly before they escalate into larger problems affecting overall customer satisfaction. Ultimately, investing time and resources into logistics management will pay off by safeguarding your products' journey from factory floor to end-user.

Workforce Issues and Skill Gaps

In the realm of quality control in China, workforce issues and skill gaps are pivotal challenges that manufacturers must navigate. The rapid evolution of technology and market demands has outpaced the existing skill sets of many workers, leading to a pressing need for training and development. Addressing these gaps is essential to ensure that quality standards in China meet both domestic expectations and international benchmarks.

Training and Development Needs

Training and development needs are critical components for effective quality control in China. Manufacturers must invest in comprehensive training programs that equip employees with the necessary skills to uphold quality standards. With an array of inspection companies in China offering specialized training, businesses can enhance their workforce's capability to meet the four types of quality control: process control, acceptance sampling, statistical process control, and continuous improvement.

Furthermore, ongoing professional development fosters a culture of excellence within organizations. By promoting continuous learning opportunities, companies can adapt to changing regulations while ensuring their teams remain proficient in modern practices related to quality assurance. This proactive approach not only boosts employee confidence but also enhances overall product quality.

Retention of Skilled Workers

Retention of skilled workers poses another significant challenge within the landscape of quality control in China. The manufacturing sector often experiences high turnover rates due to competitive job markets where talent is highly sought after by various industries. Companies focusing on retaining skilled workers must create an engaging work environment that emphasizes career growth alongside competitive compensation packages.

Additionally, fostering strong company culture plays a crucial role in keeping employees invested in their roles related to quality assurance. When workers feel valued and see potential for advancement within their organization, they are more likely to stay committed long-term—ultimately benefiting the company's overall performance in maintaining high-quality outputs. Thus, addressing retention strategies is vital for sustaining effective quality control processes.

Cultural Differences in Quality Perception

Cultural differences significantly influence perceptions surrounding quality control in China as well as its implementation across various sectors. In some cases, there may be a disconnect between local expectations regarding product standards versus those held by international partners or consumers—leading to confusion or frustration during inspections or audits conducted by inspection companies in China. Understanding these cultural nuances is essential for effective communication about what constitutes good quality.

Moreover, businesses must recognize that attitudes toward failure can vary culturally; while some cultures might view mistakes as learning opportunities, others may see them as unacceptable shortcomings impacting overall reputation—in turn affecting how individuals approach their roles within the framework of quality assurance processes. Bridging this gap requires sensitivity towards cultural values while establishing clear guidelines on maintaining high-quality production practices consistent with global standards.

In conclusion, addressing workforce issues related specifically to training needs and retention strategies will enable manufacturers operating under the umbrella of “Does China have good quality?” rhetoric not just survive but thrive amidst evolving challenges posed by globalization's impact on manufacturing dynamics today.

Technological Integration in Quality Control

In the ever-evolving landscape of quality control in China, technological integration has emerged as a crucial element for manufacturers aiming to enhance their processes. The adoption of tools such as automation and artificial intelligence (AI) not only streamlines operations but also significantly improves accuracy in quality assessments. As companies grapple with the question, Does China have good quality? it becomes evident that leveraging technology is key to elevating standards and ensuring compliance with both local and international benchmarks.

Role of Automation and AI

Automation plays a pivotal role in redefining quality control processes in China by minimizing human error and increasing efficiency. By employing AI-driven systems, manufacturers can conduct real-time inspections, thus allowing for immediate corrective actions when defects are detected. This shift toward automation raises an important query: what are the quality standards in China? The answer lies in the ability of these technologies to adhere to rigorous protocols while continuously improving product output.

Moreover, automation facilitates better tracking of production metrics, enabling manufacturers to assess their performance against established benchmarks effectively. With AI's capability to analyze vast amounts of data rapidly, businesses can make informed decisions about their supply chains and production methods. As manufacturers increasingly rely on inspection companies in China for third-party evaluations, integrating these advanced technologies becomes essential for maintaining competitiveness.

Data Management and Analytics

Data management is another cornerstone of effective quality control in China; it allows organizations to harness insights from various stages of production efficiently. By utilizing robust analytics platforms, manufacturers can identify trends that inform their quality assurance strategies while addressing the question: does China have quality control? The answer hinges on how well companies leverage data analytics to drive continuous improvement initiatives.

Effective data management also aids compliance with international standards by providing a clear audit trail that demonstrates adherence to regulations. With access to real-time data on production processes, businesses can pinpoint areas needing enhancement or adjustment swiftly. This proactive approach not only mitigates risks but also aligns with the four types of quality control widely recognized across industries—prevention, appraisal, internal failure, and external failure—ensuring comprehensive oversight throughout operations.

Challenges of Implementation

Despite the undeniable advantages technology brings to quality control efforts in China, challenges remain when implementing these solutions effectively. One significant hurdle is the initial investment required for advanced automation systems and data analytics tools; many smaller enterprises may find this financially daunting. Furthermore, there’s often resistance from employees who may be apprehensive about adapting to new technologies or fear job displacement—a concern that must be addressed head-on.

Another challenge arises from integrating new technologies into existing workflows without disrupting productivity levels or compromising product integrity during transition periods. Organizations must ensure they provide adequate training programs that equip workers with skills necessary for operating sophisticated systems while fostering a culture conducive to technological adaptation. Ultimately, overcoming these challenges will play a crucial role in determining whether Chinese manufacturing can consistently deliver high-quality products that meet global standards.

Legal Considerations in Quality Control

Navigating the legal landscape of quality control in China can feel like walking through a maze—one filled with regulations, standards, and potential pitfalls. Understanding the nuances of intellectual property issues is crucial for manufacturers seeking to maintain high-quality outputs while safeguarding their innovations. With the right knowledge and strategies, companies can effectively address these challenges and ensure robust quality control.

Understanding Intellectual Property Issues

When it comes to quality control in China, understanding intellectual property (IP) issues is paramount for any business operating in this vast market. Does China have quality control? Absolutely, but without strong IP protections, your innovations may be at risk of infringement or theft. To navigate these waters successfully, manufacturers must familiarize themselves with China's IP laws and the various types of protections available—like patents and trademarks—ensuring that their unique processes and products are secure from unauthorized use.

Furthermore, knowing what the quality standards in China entail helps businesses align their operations with local regulations while protecting their intellectual assets. The four types of quality control—process control, acceptance sampling, statistical process control, and continuous improvement—can all be impacted by how well a company manages its IP rights. In an environment where imitation can be rampant, prioritizing IP awareness not only enhances product integrity but also fortifies overall brand reputation.

Dispute Resolution in Manufacturing

Disputes are an unfortunate reality in any manufacturing process; however, understanding how to resolve them efficiently is key to maintaining effective quality control in China. Companies often find themselves embroiled in conflicts over contractual obligations or product specifications that can disrupt production timelines and affect overall output quality. Knowing what are the 4 types of Quality Control aids businesses in identifying potential areas for disputes before they escalate.

In many cases, having a clear dispute resolution mechanism outlined within contracts can save time and resources when conflicts arise. Moreover, utilizing mediation or arbitration services tailored for international disputes can lead to quicker resolutions compared to traditional litigation routes—especially important when dealing with cross-border suppliers or clients who may have different cultural perspectives on conflict management. By proactively addressing potential disputes through structured approaches, companies can maintain focus on upholding high-quality standards amidst challenges.

Role of AC&E in Navigating Legal Challenges

The role of AC&E (Advisory Counsel & Expertise) becomes increasingly significant as companies seek guidance on navigating legal challenges related to quality control in China. With expertise spanning various sectors—including manufacturing compliance and regulatory affairs—they provide invaluable insights into both local laws and international standards compliance that impact how companies manage their operations effectively. Does China have good quality? The answer often lies not just within production processes but also within legal frameworks that support those processes.

AC&E professionals help businesses understand inspection companies in China that specialize in ensuring adherence to established quality benchmarks while addressing potential legal pitfalls associated with non-compliance or subpar goods entering the market. By leveraging AC&E's expertise alongside robust internal practices focused on continuous improvement—such as implementing data-driven analytics for monitoring performance—companies position themselves favorably against competitors who might overlook these critical aspects of legal navigation within their supply chains.

Conclusion

As the manufacturing landscape in China continues to evolve, overcoming quality control challenges becomes paramount. Quality control in China is not just a buzzword; it's a necessity for businesses aiming to thrive in a competitive global market. By understanding and addressing the complexities of quality assurance, companies can ensure their products meet international standards and consumer expectations.

Overcoming Quality Control Challenges

To answer the question, Does China have quality control?—the simple answer is yes, but it requires navigating a labyrinth of regulations and standards. Implementing effective strategies to manage diverse suppliers and conducting thorough inspections can significantly mitigate risks associated with poor quality products. Moreover, engaging with reputable inspection companies in China can enhance the reliability of quality checks throughout the manufacturing process.

Quality assurance isn't merely about compliance; it’s about fostering a culture that prioritizes excellence across all levels of production. By focusing on training and development needs, manufacturers can bridge skill gaps that often hinder effective quality control measures. Ultimately, building robust systems that address these challenges will lead to improved product reliability and customer satisfaction.

Future Trends in Chinese Manufacturing

Looking ahead, what are the future trends in Chinese manufacturing? The integration of advanced technologies such as automation and AI will play a crucial role in enhancing quality control processes. These innovations promise not only to streamline operations but also to elevate overall product standards—addressing concerns over whether China has good quality once and for all.

Additionally, as global consumers become more discerning about product origins and standards, manufacturers must adapt by adopting international benchmarks for quality assurance. This shift will likely lead to increased collaboration between local firms and international partners aiming for compliance with global quality standards in China. Thus, staying ahead of these trends will be essential for companies looking to maintain their competitive edge.

The Role of Legal Expertise in Quality Assurance

In navigating the complexities of quality control in China, legal expertise becomes invaluable. Understanding intellectual property issues is critical when dealing with suppliers or partners who may have differing interpretations of what constitutes acceptable quality standards in China. Furthermore, effective dispute resolution strategies are essential for mitigating risks that arise from manufacturing discrepancies or contractual disagreements.

The role of AC&E (Advisory Compliance & Enforcement) cannot be understated when it comes to ensuring compliance with both local laws and international regulations governing product safety and efficacy. By leveraging legal expertise within your organization or through external partnerships, you can create a framework that not only supports robust quality assurance practices but also protects your business interests effectively.