Introduction

In today's global marketplace, ensuring product quality is more crucial than ever, and AQL inspection plays a pivotal role in this process. AQL, or Acceptable Quality Level, serves as a benchmark for identifying acceptable defect rates in products, guiding businesses on what constitutes satisfactory quality. As companies increasingly source products from countries like China, understanding the nuances of AQL inspection becomes essential for maintaining high standards.

Understanding AQL Inspection Basics

So, what is AQL inspection? At its core, it’s a sampling method used to determine the quality of goods by evaluating a specific number of items from a larger batch. By examining these samples against predetermined criteria, businesses can make informed decisions about whether to accept or reject entire shipments based on the findings from their AQL inspections.

Importance of AQL Standards

The significance of adhering to established AQL standards cannot be overstated; they provide a consistent framework that helps businesses maintain product quality across various industries. Without these standards, companies may face inconsistent quality levels that can lead to dissatisfied customers and damaged reputations. Understanding what is the industry standard for AQL empowers organizations to set realistic expectations and ensures alignment with global best practices.

Quality Control in China Explained

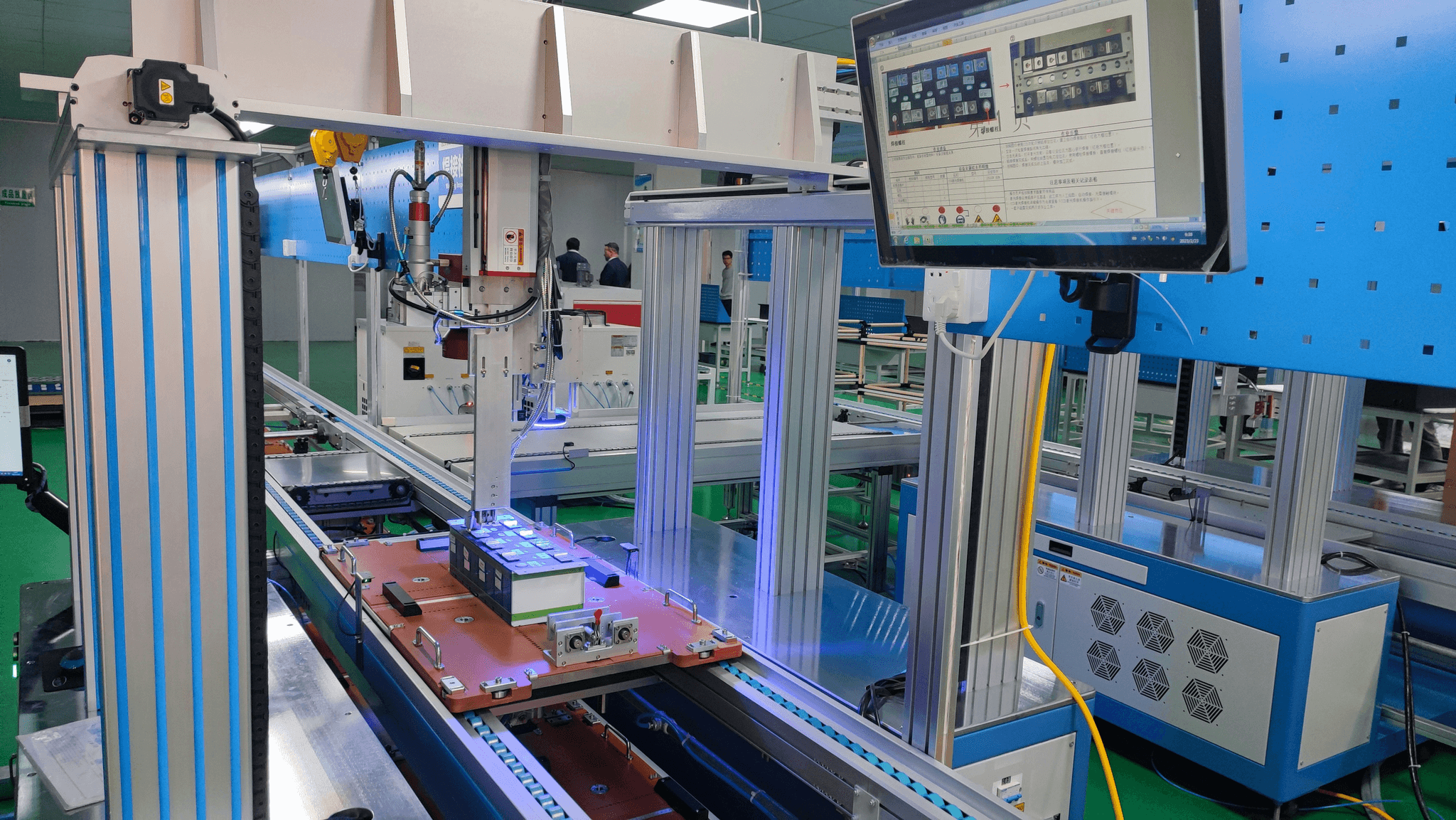

Quality control in China presents unique challenges due to its vast manufacturing landscape and varying production practices. Implementing effective AQL inspections is vital for navigating these complexities and ensuring that imported goods meet specific quality criteria. By leveraging proper AQL methodologies along with local expertise, businesses can enhance their overall quality assurance processes while minimizing risks associated with subpar products.

What is AQL Inspection?

AQL inspection, or Acceptable Quality Level inspection, is a critical method used to assess the quality of products during manufacturing. It focuses on determining whether the number of defective items in a sample falls within an acceptable range, thus ensuring that the overall quality meets predefined standards. When asking What is AQL inspection?, one should consider it as a systematic approach to quality control that helps businesses maintain product integrity while minimizing costs.

Defining AQL and Its Purpose

AQL stands for Acceptable Quality Level, which defines the maximum number of defective items considered acceptable in a batch of products. The purpose of AQL is to provide manufacturers and suppliers with a clear guideline on how many defects are tolerable without compromising product quality. By establishing these thresholds, companies can effectively manage risks associated with poor-quality goods while maintaining customer satisfaction.

The Role of AQL in Quality Management

In the realm of quality management, AQL plays an essential role by offering a standard framework for evaluating product quality during inspections. This framework not only helps in identifying defects but also aids organizations in implementing corrective measures when necessary. As businesses strive for excellence, understanding What is the industry standard for AQL? becomes crucial; it ensures that they align their practices with globally recognized benchmarks.

Real-World Applications of AQL

AQL inspections find their application across various industries such as textiles, electronics, and food production—each having specific requirements tailored to their unique challenges. For instance, in electronics manufacturing, an AQL level might be set at 1.5 to ensure minimal defects in high-stakes components like circuit boards. In contrast, food production may adopt different levels based on safety standards; hence understanding What does an AQL of 1.5 mean? becomes vital for compliance and consumer safety.

What is the Industry Standard for AQL?

Understanding the industry standard for AQL is crucial for any business looking to maintain high-quality products while minimizing defects. AQL, or Acceptable Quality Level, serves as a benchmark that defines the maximum number of defective items considered acceptable in a sample batch. This standard varies across industries and can influence everything from manufacturing processes to supplier relationships.

Common AQL Levels Across Industries

Different industries have established various common AQL levels that reflect their specific quality requirements. For example, the textile industry may operate with an AQL of 2.5, while electronics might demand stricter standards at 0.65 due to safety concerns and functionality issues. Understanding these common levels helps businesses align their quality control measures with industry expectations and customer satisfaction.

In addition, certain sectors like pharmaceuticals may require even tighter controls, often utilizing an AQL of 0.1 or lower to ensure product safety and efficacy. By knowing what is considered acceptable in their respective markets, companies can tailor their aql inspection processes accordingly and avoid costly mistakes down the line.

Comparing AQL Standards Globally

When exploring what is the industry standard for AQL globally, it becomes evident that cultural differences and regulatory frameworks play significant roles in shaping these standards. For instance, European countries often adopt stricter quality control measures compared to some Asian manufacturers due to different consumer protection laws and market expectations.

Moreover, global businesses must navigate varying standards when sourcing materials or products internationally; this can complicate supplier selection significantly if not managed correctly. Companies engaged in international trade should be well-versed in these differences to ensure compliance with local regulations while maintaining consistent quality through effective aql inspection practices.

How AQL Affects Supplier Selection

A company's choice of suppliers heavily hinges on their adherence to accepted AQL standards; this not only impacts product quality but also affects overall operational efficiency. When evaluating potential suppliers, businesses must consider how well they align with specific aql inspection criteria relevant to their industry needs.

Furthermore, suppliers who consistently meet or exceed established AQL levels are more likely to foster long-term partnerships based on trust and reliability—essential ingredients for successful collaborations in today's competitive landscape. Ultimately, understanding how aql influences supplier selection can empower organizations to make informed decisions that lead to superior product offerings and enhanced customer satisfaction.

What is the ISO for AQL Sampling?

Understanding the relationship between AQL inspection and ISO standards is crucial for businesses aiming to maintain high-quality products. The International Organization for Standardization (ISO) provides a framework that enhances the reliability of AQL inspections and ensures consistency across industries. By adhering to ISO standards, companies can significantly improve their quality control processes, especially in regions like China where manufacturing practices can vary widely.

Introduction to ISO 2859

ISO 2859 is the standard that outlines acceptance sampling procedures using AQL inspection methods. This standard provides guidelines on how to determine sample sizes and acceptance criteria based on specified quality levels. Essentially, it helps organizations answer the question: What is the industry standard for AQL? With a clear structure in place, businesses can confidently navigate their quality assurance processes.

Key Guidelines Under ISO Standards

Key guidelines under ISO 2859 include defining acceptable quality levels (AQL), determining sample sizes based on lot size, and establishing acceptance or rejection criteria for inspection results. These guidelines ensure that inspections are both statistically valid and practical in real-world applications, thus reducing risks associated with defective products. When businesses ask themselves, What does an AQL of 1.5 mean? they can refer back to these standards for clarity on how to interpret their findings effectively.

Benefits of ISO Compliance for AQL

By following these established standards, companies can demonstrate their commitment to maintaining high-quality production processes while minimizing defects—a crucial aspect of effective quality control in China. Furthermore, compliance with ISO standards often leads to improved operational efficiency and reduced costs over time due to fewer errors and rework requirements.

What Does an AQL of 1.5 Mean?

When diving into the world of AQL inspection, one often encounters various values that dictate quality standards. An Acceptable Quality Level (AQL) of 1.5 is particularly noteworthy as it indicates a balance between acceptable defects and the need for quality assurance. Understanding what this value signifies can be crucial for businesses aiming to implement effective quality control in China or elsewhere.

Understanding AQL Values

AQL values are numerical representations that help define the maximum number of defective items considered acceptable during a random sampling inspection. In simple terms, an AQL of 1.5 means that out of a sample size, 1.5% can be defective without failing the inspection process. This percentage directly influences what is deemed acceptable in various industries, essentially guiding suppliers on how to maintain product quality while minimizing costs.

In the context of What is AQL inspection?, it's essential to recognize that these values serve as benchmarks for evaluating product batches' quality during inspections. For instance, if a batch consists of 1,000 units with an AQL level set at 1.5, no more than 15 defects should be found in the sample inspected to pass quality standards successfully. Thus, understanding these values empowers businesses to make informed decisions about supplier selection and product acceptance.

Implications of an AQL of 1.5

An AQL value of 1.5 carries significant implications for manufacturers and importers alike; it sets clear expectations regarding defect tolerance levels within products being inspected under defined conditions like ISO standards for sampling procedures (specifically ISO 2859). This level suggests a moderate tolerance for defects but underscores the need for diligence in maintaining quality throughout production processes.

For companies engaged in Quality Control in China, adhering to an AQL of 1.5 means they must ensure their suppliers consistently meet this standard—otherwise, they risk accepting subpar products into their inventory or facing costly returns and reputational damage later on down the supply chain. Moreover, using this specific level can signal to potential partners or clients that your organization prioritizes high-quality outputs while still recognizing practical limitations inherent in manufacturing.

Ultimately, understanding what does an AQL of 1.5 mean helps stakeholders navigate complexities associated with product inspections effectively and ensures compliance with industry standards globally.

When to Use Specific AQL Levels

Choosing when to apply particular AQL levels requires careful consideration based on factors such as industry norms, customer expectations, and regulatory requirements—especially when asking What is the industry standard for AQL? While many industries have established common benchmarks (like an AQL of 2.5 or even stricter levels), opting for a tighter threshold like 1.5 may be warranted depending on specific circumstances.

For instance, if you're dealing with high-stakes products such as medical devices or aerospace components where safety is paramount, employing an AQL value closer to or below 1 might be advisable—even if it increases costs slightly due to more rigorous inspections required under ISO guidelines (like those outlined by ISO for AQL sampling). Conversely, less critical consumer goods may allow room for higher tolerances without jeopardizing overall satisfaction; thus using a higher level could streamline operations while still maintaining adequate oversight.

In summary, knowing when and why you should use specific levels like an AQL of 1.5 not only enhances your approach toward supplier management but also fosters trust among customers who expect top-notch quality from your products—all crucial elements in today's competitive market landscape.

Conducting Effective AQL Inspections

AQL inspections are crucial for maintaining product quality, especially in a global market where standards can vary significantly. To ensure that your quality control processes are effective, it’s essential to prepare adequately for these inspections. This preparation includes understanding what is AQL inspection, the industry standards that apply, and how ISO guidelines influence the sampling process.

Preparing for AQL Inspections

Start by clearly defining your quality objectives and selecting the appropriate AQL level based on your specific product requirements and industry standards. Understanding what does an AQL of 1.5 mean in practical terms will guide you in determining acceptable defect rates and help set realistic expectations with suppliers.

Next, gather all necessary documentation related to your products, such as specifications sheets and previous inspection reports. These documents provide a solid foundation for assessing whether your products meet established criteria during the inspection process. Additionally, ensure that your team is trained on both the technical aspects of AQL sampling and the nuances of quality control in China to navigate any challenges effectively.

Tools and Techniques for AQL Testing

When it comes to tools and techniques for AQL testing, having the right resources at your disposal can make all the difference. Common tools include statistical software for sample size determination based on accepted defect levels as well as physical measuring devices tailored to specific product types. Utilizing these tools ensures that you adhere closely to what is the ISO for AQL sampling guidelines while also enhancing accuracy during inspections.

Moreover, consider employing visual inspection techniques alongside automated testing methods whenever possible; this combination often yields more reliable results than either method alone. Training inspectors in both qualitative assessments (like visual checks) and quantitative measurements (like dimensional checks) will enhance their ability to identify defects effectively during an aql inspection process.

Common Mistakes to Avoid

Even seasoned professionals can fall into traps when conducting AQL inspections if they aren't careful! One common mistake is neglecting proper sample size calculations based on what is the industry standard for AQL; using insufficient sample sizes can lead to misleading results about product quality. Always refer back to established guidelines before proceeding with any inspections.

Another frequent error involves failing to document findings thoroughly during an aql inspection; without clear records, it becomes challenging to track trends or justify decisions down the line regarding supplier performance or product adjustments. Lastly, don’t overlook communication with suppliers—keeping them informed about expectations helps build trust while ensuring everyone understands their roles in upholding quality standards.

Enhancing Quality Control in China

Quality Control in China can be a challenging endeavor, but with the right strategies, it can lead to significant improvements in product quality and supplier relationships. Companies must adopt a proactive approach to Quality Assurance, focusing on clear communication, regular audits, and robust training programs for local staff. By implementing these strategies, businesses can ensure that their AQL inspection processes align with both global standards and local practices.

Strategies for Quality Assurance in China

To effectively enhance quality assurance in China, companies should start by establishing clear quality benchmarks based on AQL standards. This involves defining what is acceptable under different conditions and ensuring that all stakeholders understand these parameters. Additionally, regular training sessions on AQL inspection techniques will help maintain consistency and adherence to industry standards across teams.

Moreover, leveraging technology can streamline the AQL inspection process significantly. Implementing software solutions that track production metrics and quality reports allows for real-time monitoring of compliance with AQL levels. By embracing such innovations, companies not only improve their inspection accuracy but also foster a culture of continuous improvement.

Lastly, fostering strong relationships with suppliers is crucial for effective quality control in China. Regular communication about expectations regarding AQL inspections helps build trust and ensures that suppliers are committed to meeting the required standards consistently. When suppliers understand the importance of adhering to an agreed-upon AQL level—whether it’s 1.5 or another figure—they are more likely to prioritize quality throughout their production processes.

Partnering with Reliable Inspectors

Finding reliable inspectors is paramount when conducting effective AQL inspections in China. It’s essential to partner with professionals who have a deep understanding of both local manufacturing practices and international quality standards like ISO 2859 for sampling plans. These inspectors should not only be well-versed in what is the industry standard for AQL but also have a proven track record of successful inspections.

When selecting an inspection partner, consider their experience within your specific industry as well as their familiarity with various AQL levels applicable to your products. This ensures they can accurately assess compliance during inspections while providing valuable insights into potential areas for improvement based on past experiences with similar products or manufacturers.

Additionally, working closely with your chosen inspectors allows you to gain deeper insights into common pitfalls within your supply chain related to Quality Control in China. They can provide recommendations on how best to navigate challenges while ensuring adherence to necessary regulations and maintaining high-quality output through effective use of AQL sampling methods.

Navigating Regulatory Challenges

Navigating regulatory challenges is often one of the trickiest aspects of maintaining quality control in China; however, understanding local laws can give businesses an edge during inspections like those governed by ISO standards for AQL sampling procedures. Companies must familiarize themselves not just with national regulations but also regional guidelines that may affect product safety and compliance requirements related to specific industries.

Establishing a comprehensive compliance framework helps mitigate risks associated with regulatory non-compliance during your AQL inspections process—especially when dealing directly with suppliers who may have differing interpretations of these regulations based on their own experiences or knowledge gaps regarding what constitutes acceptable practice under various circumstances.

Moreover, engaging legal support familiarized with both international trade laws and Chinese regulations can further bolster your efforts toward successful navigation through complex regulatory landscapes impacting Quality Control in China overall—and subsequently improving outcomes from your company’s commitment towards maintaining high-quality products through rigorous adherence towards established benchmarks like those outlined by relevant ISO guidelines regarding proper handling during an effective assessment via appropriate use of defined parameters within any given context surrounding what does an AQL of 1.5 mean?

The Importance of Legal Support in AQL

Navigating the world of AQL inspection can be complex, especially when it comes to ensuring compliance with both international standards and local regulations. Legal support plays a crucial role in this process, providing companies with the guidance they need to adhere to quality control measures effectively. By understanding the legal landscape surrounding AQL, businesses can mitigate risks and enhance their operational efficiency.

How AC&E Can Assist with AQL Compliance

AC&E offers comprehensive services that help organizations understand what is AQL inspection and how it applies to their specific industry needs. Their expertise includes navigating ISO standards for AQL sampling, ensuring clients are well-prepared for inspections and compliant with relevant regulations. With AC&E's support, businesses can focus on improving their quality control in China while leaving the complexities of legal compliance to seasoned professionals.

Moreover, AC&E provides tailored solutions that address common pain points related to supplier relationships and regulatory challenges. This means companies can establish robust quality management systems that not only meet but exceed industry standards for AQL. By leveraging AC&E's resources, organizations can enhance their reputation for quality assurance and build lasting partnerships with suppliers.

Legal Considerations in Quality Control

In the realm of quality control, particularly concerning what is the industry standard for AQL, understanding legal considerations is paramount. Companies must be aware of local laws regarding product safety and consumer protection that may impact their quality assurance practices. Failing to comply with these regulations could lead to significant financial penalties or damage to a brand’s reputation.

Additionally, businesses should consider how an AQL of 1.5 might influence their legal obligations regarding product returns or warranties. Having clear contractual agreements outlining quality expectations helps mitigate disputes between suppliers and manufacturers over product defects or non-compliance issues during inspections. Thus, integrating legal considerations into your overall strategy enhances your ability to maintain high-quality standards while protecting your business interests.

Building Trust with Suppliers through Legal Measures

Building trust with suppliers is essential for successful collaborations in any industry; this is especially true when discussing what does an AQL of 1.5 mean for product expectations and delivery timelines. Implementing clear legal frameworks establishes mutual accountability between parties involved in the supply chain process while fostering transparency about quality control metrics such as those defined by ISO standards for AQL sampling.

Furthermore, having legally binding agreements ensures that all parties are aligned on what constitutes acceptable quality levels during inspections like those mandated by an aql inspection protocol. This not only promotes a culture of accountability but also encourages open communication about potential issues before they escalate into larger problems affecting production timelines or financial outcomes.

Ultimately, integrating legal measures into supplier relationships enhances trustworthiness and reliability—key components necessary for achieving success in today’s competitive market landscape where maintaining high-quality benchmarks remains critical.

Conclusion

In wrapping up our exploration of AQL inspection, it’s clear that understanding what AQL inspection is and its importance in quality control cannot be overstated. From defining the industry standards for AQL to delving into ISO sampling guidelines, we’ve seen how these frameworks not only enhance product quality but also foster trust between suppliers and buyers. As businesses increasingly rely on AQL to maintain high standards, recognizing the implications of specific AQL values, such as an AQL of 1.5, becomes crucial in decision-making processes.

Key Takeaways for AQL Success

To achieve success with AQL inspection, it's essential to grasp its fundamental principles and applications across various industries. The industry standard for AQL varies by sector, so knowing these benchmarks will help you align your quality expectations with your suppliers’ capabilities. Moreover, a solid understanding of what an AQL of 1.5 means can guide you in setting realistic goals for product quality while navigating the complexities of Quality Control in China.

Next Steps for Implementing AQL

Implementing effective AQL inspection protocols involves several actionable steps that can enhance your quality management practices. Begin by familiarizing yourself with the ISO standards related to AQL sampling—specifically ISO 2859—to ensure compliance and improve your inspection processes. Additionally, consider collaborating with experienced inspectors who understand the nuances of Quality Control in China; their expertise can help streamline inspections and mitigate risks associated with non-compliance.

The Value of Continuous Quality Improvement

Continuous quality improvement is integral to maintaining a competitive edge in today’s market landscape where consumer expectations are ever-increasing. By regularly revisiting your approach to what is the industry standard for AQL and adjusting your strategies accordingly, you can foster a culture that prioritizes excellence at every stage of production. Ultimately, embracing an ongoing commitment to refining your processes will not only bolster product reliability but also strengthen relationships with suppliers through transparency and accountability.