Introduction

The landscape of global manufacturing is undergoing a significant transformation as companies reconsider their strategies in light of evolving economic and geopolitical conditions. The question on many minds is: Are manufacturers moving away from China? This shift is not merely a trend; it reflects deeper issues such as rising labor costs, supply chain vulnerabilities, and increasing geopolitical tensions that have led to a reevaluation of where production should take place.

Understanding the Shift in Manufacturing

Understanding the shift in manufacturing involves recognizing how interconnected global economies have become and how quickly they can pivot. Moving manufacturing out of China has become a focal point for many businesses seeking greater stability and resilience in their supply chains. As companies explore alternatives, they are also weighing the pros and cons of diversifying their production locations to mitigate risks associated with over-reliance on one country.

The Driving Forces Behind Relocation

Several driving forces are prompting foreign companies to leave China, with rising labor costs being one of the most prominent factors. Inflationary pressures have made it increasingly expensive to maintain operations there, pushing firms to seek more cost-effective solutions elsewhere. Additionally, geopolitical tensions are creating an environment where stability is paramount; businesses are now prioritizing reliability over mere cost savings when considering which country will replace China manufacturing.

The Legal Implications of Leaving China

The legal implications of leaving China cannot be overlooked as companies embark on this complex journey. Navigating international laws, trade agreements, and local regulations becomes crucial when relocating production facilities or establishing new partnerships abroad. Moreover, understanding these legal frameworks ensures that organizations can avoid pitfalls during this transition while optimizing their strategies for moving manufacturing out of China effectively.

What Companies Are Moving Production Out of China

As the trend of moving manufacturing out of China gains momentum, several high-profile companies are reevaluating their supply chains and manufacturing strategies. The question on everyone's mind is: Are manufacturers moving away from China? The answer is a resounding yes, with industry giants leading the charge toward diversification and resilience.

The Case of Apple and Its Supply Chain Strategy

Apple has become a poster child for companies moving production out of China, driven by rising labor costs and geopolitical tensions. In an effort to mitigate risks associated with over-reliance on a single country, Apple has begun shifting its manufacturing focus to countries like India and Vietnam. This strategic realignment not only helps in reducing costs but also ensures that Apple remains agile in adapting to global market fluctuations.

The company’s decision reflects a broader trend where other tech firms are also asking themselves: What companies are moving production out of China? Apple's move is significant because it sets a precedent for others in the tech sector to follow suit. By diversifying its supply chain, Apple aims to enhance reliability while navigating the complexities of international trade.

Nike's Diversification of Manufacturing Locations

Nike exemplifies another major player embracing change by diversifying its manufacturing locations beyond China. The sportswear giant has been proactive in relocating some production to countries such as Vietnam and Indonesia, effectively answering the question: Why are foreign companies leaving China? Rising labor costs coupled with supply chain disruptions have prompted Nike to explore more stable environments for production.

With this shift, Nike not only aims to reduce operational risks but also seeks to tap into new markets that can offer competitive advantages. As part of their strategy, they are investing heavily in local partnerships that can facilitate smoother transitions and maintain quality standards during this process. This move highlights the practicality behind moving manufacturing out of China while addressing challenges that arise from such transitions.

Other Notable Brands Making the Shift

Beyond Apple and Nike, many other notable brands are also making waves by relocating their production facilities away from China. Companies like Samsung and Adidas have joined the ranks of those reassessing their manufacturing strategies due to similar concerns about rising costs and geopolitical instability. These brands recognize that diversifying their operations will not only safeguard against potential disruptions but also align with evolving consumer preferences for ethical sourcing.

As these brands make headlines for their shifts, they contribute to an overarching narrative about which country will replace China's dominance in manufacturing. Countries like Vietnam and India are emerging as frontrunners due to their favorable labor conditions and investment incentives aimed at attracting foreign businesses seeking alternatives. In this landscape where “Are manufacturers moving away from China?” becomes increasingly relevant, businesses must weigh both pros and cons before taking action on relocating.

Which Country Will Replace China Manufacturing?

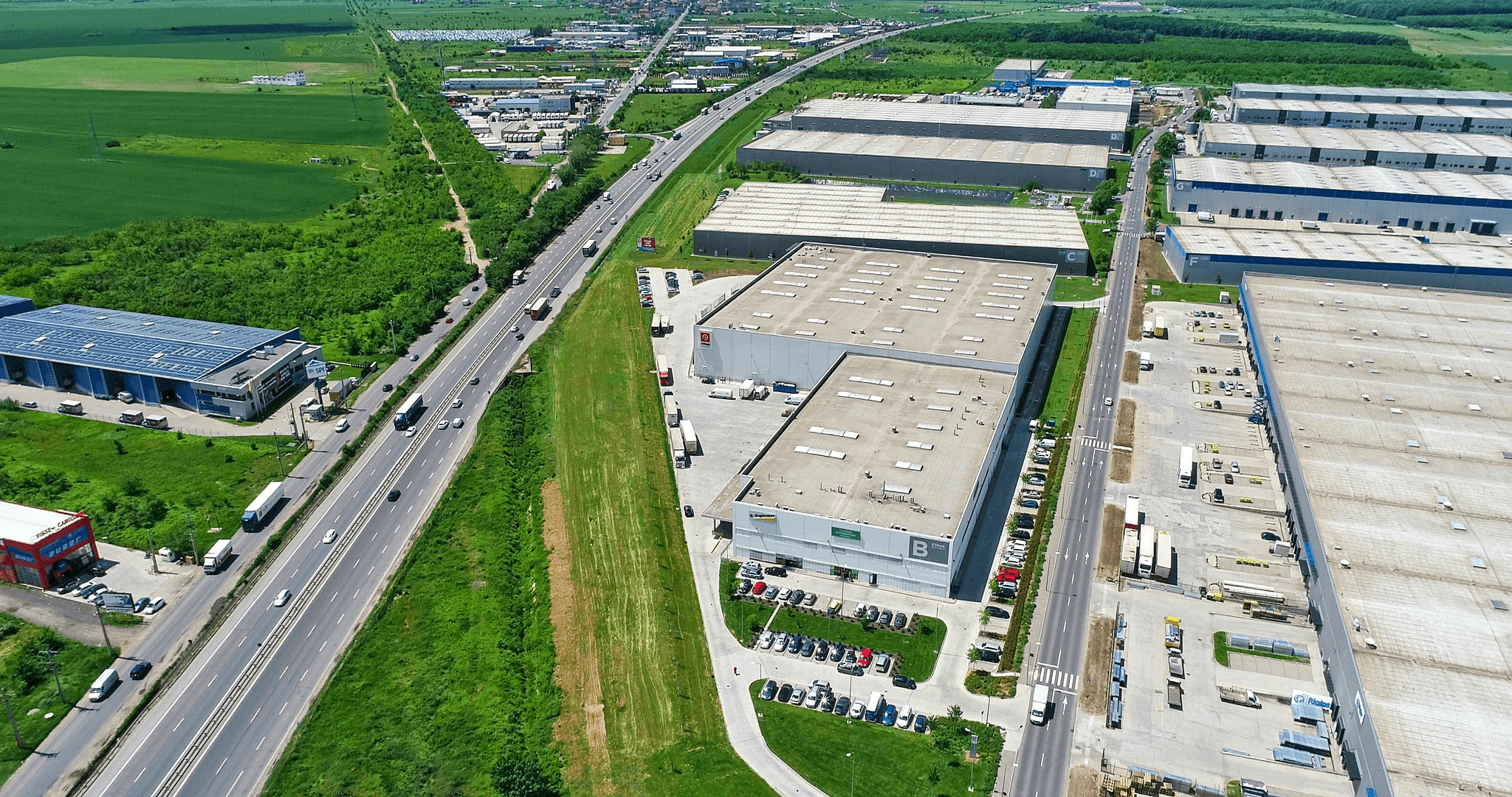

As companies increasingly consider moving manufacturing out of China, several countries are emerging as potential replacements in the global supply chain. The question on everyone's lips is, Which country will replace China manufacturing? With rising labor costs, geopolitical tensions, and supply chain disruptions prompting foreign companies to rethink their strategies, nations like Vietnam, India, and Mexico are stepping up to the plate. Each of these countries offers unique advantages that could make them attractive alternatives for manufacturers seeking stability and reliability.

Vietnam's Rise as a Manufacturing Hub

Vietnam has emerged as a frontrunner in the race to replace China manufacturing due to its competitive labor costs and favorable trade agreements. Many companies are moving production out of China to take advantage of Vietnam's burgeoning infrastructure and skilled workforce. Notably, brands like Samsung have significantly invested in Vietnamese facilities, showcasing the country's potential as a manufacturing powerhouse.

The Vietnamese government has also been proactive in attracting foreign investment by simplifying regulations and offering tax incentives. This has made it easier for businesses to establish operations without navigating a maze of bureaucratic red tape. As more firms recognize the benefits of relocating their production lines, it's clear that Vietnam is poised for continued growth in this sector.

However, while Vietnam presents numerous opportunities for manufacturers looking for alternatives to China, challenges remain. Infrastructure development must keep pace with rapid industrialization to avoid bottlenecks that could disrupt supply chains. Companies must weigh these factors carefully when considering whether moving manufacturing out of China is worth it.

India's Growing Appeal for Foreign Investment

India is quickly becoming an attractive destination for foreign companies looking to diversify their manufacturing bases away from China. With a massive workforce and an increasing focus on technology-driven industries, India offers both scale and innovation that many manufacturers find appealing. The Indian government's push towards initiatives like Make in India aims to create a more conducive environment for foreign investment.

In addition to its labor pool, India's growing middle class presents new market opportunities for companies that establish local production facilities. This dual benefit—manufacturing goods while simultaneously catering to domestic demand—makes India particularly enticing for brands seeking sustainable growth strategies amid shifting geopolitical landscapes. As questions arise about why foreign companies are leaving China, India's advantages become even more pronounced.

Nonetheless, challenges such as regulatory hurdles and infrastructural limitations still exist within India’s complex business environment. Manufacturers must navigate these obstacles carefully if they want successful transitions from Chinese factories back home or abroad. Ultimately, those willing to invest time into understanding the Indian market may find themselves well-rewarded.

The Potential of Mexico in the Global Market

Mexico stands out as another contender when discussing which country will replace China manufacturing due to its strategic location near North America’s largest consumer market—the United States. This proximity not only reduces shipping times but also minimizes tariffs under trade agreements like USMCA (United States-Mexico-Canada Agreement). Consequently, many companies are moving production out of China toward Mexican facilities.

Moreover, Mexico boasts an established manufacturing ecosystem with expertise across various sectors including automotive and electronics—making it an ideal candidate for firms looking at diversifying their operations away from Asia altogether. Brands such as Ford have already begun shifting portions of their supply chains southward due largely because they recognize both cost savings along with logistical efficiencies available within this region.

However appealing Mexico may seem on paper; challenges remain regarding security concerns related directly tied into drug cartel activities impacting certain areas across the country alongside fluctuating currency values affecting profitability margins over time too! Thus evaluating all aspects—including moving manufacturing out of china pros and cons—is essential before making any final decisions about relocation efforts underway today!

Are Manufacturers Moving Away from China?

The landscape of global manufacturing is shifting, and the question on everyone's lips is: are manufacturers moving away from China? The answer, in short, is a resounding yes. A combination of rising costs, supply chain vulnerabilities, and geopolitical tensions has prompted many companies to reevaluate their dependence on Chinese production facilities.

Trends in Foreign Direct Investment

One clear indicator that manufacturers are moving out of China is the changing trends in foreign direct investment (FDI). In recent years, there has been a noticeable decline in FDI directed towards China as companies seek more stable environments for their operations. Countries like Vietnam and India are reaping the benefits as they become attractive alternatives for businesses looking to relocate manufacturing operations.

This shift reflects a broader trend where foreign companies are leaving China due to not just economic factors but also regulatory challenges and trade tensions. The allure of lower labor costs and favorable trade agreements in other countries makes them appealing destinations for those contemplating moving manufacturing out of China. As these trends continue to evolve, we can expect a more diversified global manufacturing landscape.

Case Studies of Successful Relocations

Several high-profile case studies illustrate how moving manufacturing out of China can be successfully executed. Take Apple, for instance; the tech giant has been strategically diversifying its supply chain by increasing production in countries like India and Vietnam. This move not only mitigates risks associated with over-reliance on Chinese factories but also aligns with Apple's long-term goals of sustainability and resilience.

Another notable example is Nike, which has expanded its production footprint beyond China to include locations such as Indonesia and Vietnam. By diversifying its manufacturing base, Nike can respond more flexibly to market changes while reducing exposure to potential disruptions tied solely to Chinese operations. These success stories serve as powerful examples for other brands contemplating similar moves amid ongoing discussions about why foreign companies are leaving China.

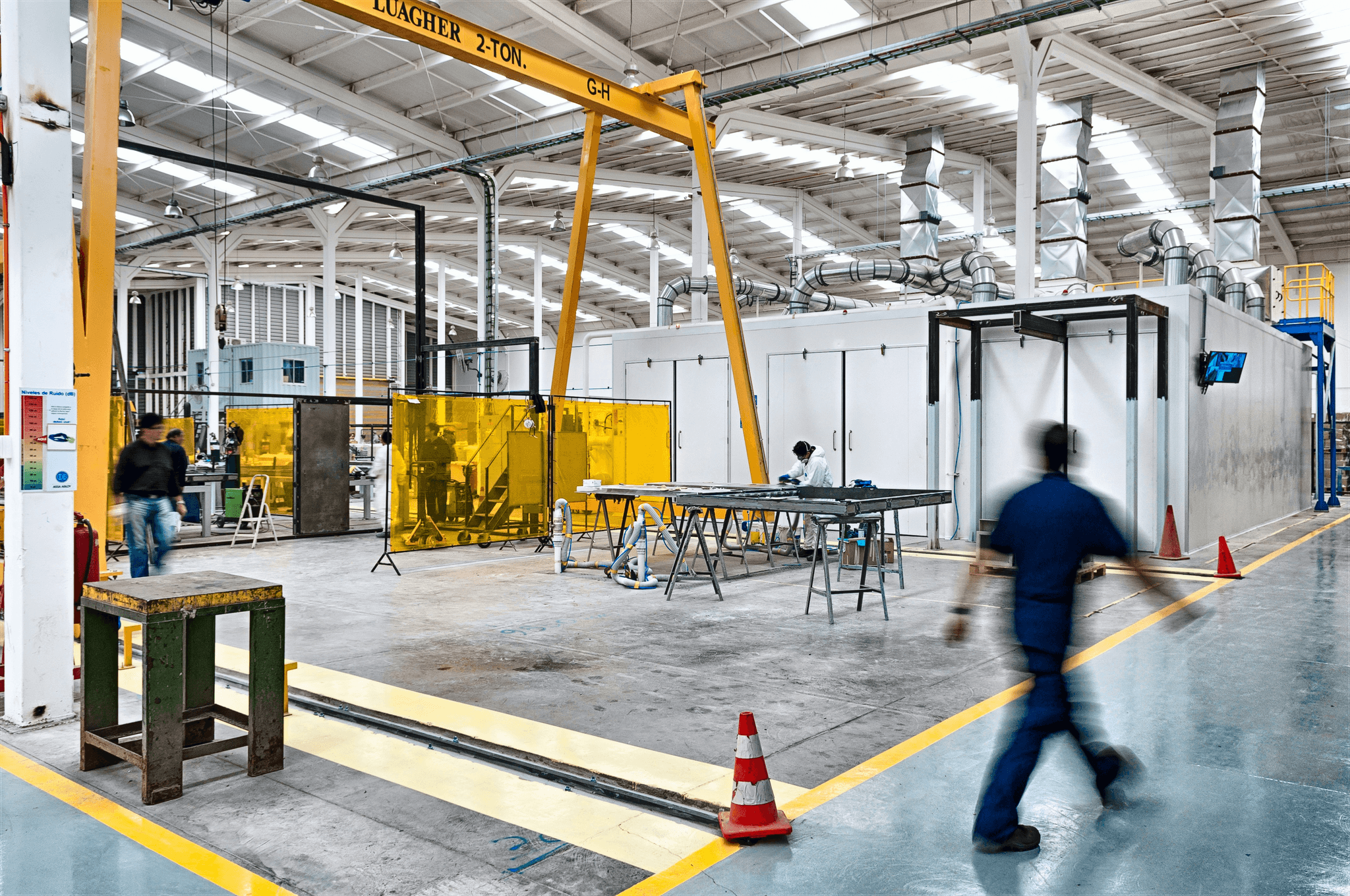

The Role of AC&E in Facilitating Transitions

As manufacturers contemplate relocating their operations, organizations like AC&E play a crucial role in facilitating transitions smoothly and efficiently. AC&E provides strategic guidance tailored specifically for businesses looking at moving manufacturing out of China by offering insights into new markets, legal compliance requirements, and logistical support during the relocation process.

Furthermore, AC&E helps navigate potential pitfalls associated with transitioning production sites while ensuring that companies maintain quality standards throughout the shift. Their expertise proves invaluable as brands weigh the pros and cons of moving manufacturing out of China against maintaining existing relationships within the country’s complex industrial ecosystem.

Moving Manufacturing Out of China Pros and Cons

The decision to relocate manufacturing operations is not one to be taken lightly. As companies ponder the question, Are manufacturers moving away from China?, they must weigh the pros and cons carefully. The landscape of global manufacturing is shifting, and understanding these dynamics is crucial for businesses considering their next steps.

Benefits of Diversifying Production Locations

One of the most significant benefits of moving manufacturing out of China is the diversification of risk. By spreading production across multiple countries, companies can mitigate potential disruptions caused by geopolitical tensions or supply chain issues that have plagued operations in China. Additionally, this strategy allows firms to tap into new markets, potentially increasing revenue streams while enhancing their overall resilience.

Another advantage lies in accessing a more skilled labor force in emerging markets like Vietnam and India. These countries are rapidly developing their capabilities and infrastructure, making them attractive alternatives for foreign investment. Companies that adapt quickly can benefit from lower labor costs while maintaining quality production standards—an essential consideration when evaluating why are foreign companies leaving China?

Challenges and Risks of Transitioning

However, transitioning manufacturing operations comes with its own set of challenges and risks. Companies may face significant upfront costs associated with establishing new facilities or retraining workers in different countries—a process that can be both time-consuming and expensive. Moreover, there may be regulatory hurdles to navigate as firms adapt to local laws and standards in their new locations.

Supply chain logistics also present a challenge; moving production out of China could lead to initial disruptions as companies establish new supplier relationships or adjust existing ones. This transitional phase can test a company's flexibility and adaptability, raising questions about whether they are prepared for such changes in operational dynamics—especially during times when what companies are moving production out of China? becomes increasingly relevant.

Balancing Cost and Quality Considerations

Balancing cost with quality considerations is another critical aspect when discussing moving manufacturing out of China pros and cons. While lower labor costs might be appealing in countries like Vietnam or India, businesses must ensure that these savings do not come at the expense of product quality or brand reputation. Striking this balance often requires extensive research into potential locations' capabilities before making any commitments.

Furthermore, companies need to consider how shifting production might affect their existing relationships with suppliers based in China—relationships built over years that contribute significantly to product quality control processes. Thus, weighing the benefits against possible pitfalls becomes essential for those contemplating which country will replace China manufacturing effectively without compromising on value.

Conclusion

The landscape of global manufacturing is undergoing a significant transformation, with many companies reassessing their strategies in light of rising costs and geopolitical tensions. In this evolving scenario, the question remains: Are manufacturers moving away from China? As we’ve explored, the shift is not merely a trend but a strategic pivot that could redefine supply chains for years to come.

Evaluating the Future of Manufacturing Strategies

Moving manufacturing out of China is becoming an increasingly viable option for businesses seeking greater flexibility and stability. Companies like Apple and Nike are leading the charge by diversifying their production locations to mitigate risks associated with reliance on a single country. This strategic evaluation is crucial as firms weigh the benefits against potential drawbacks in order to remain competitive in an ever-changing market.

Understanding the Long-Term Impacts

The long-term impacts of moving manufacturing out of China will likely ripple through global markets, altering trade dynamics and investment patterns. As foreign companies leave China, new opportunities arise for countries like Vietnam, India, and Mexico to fill the void left behind. However, it’s essential to recognize that while these shifts may enhance supply chain resilience, they also introduce challenges that must be navigated carefully.

The Importance of Legal Guidance in Transitions

Navigating the complexities involved in relocating manufacturing operations cannot be understated; this is where legal guidance becomes indispensable. Companies must consider regulatory compliance, intellectual property protections, and labor laws when exploring new manufacturing destinations. Thus, understanding why foreign companies are leaving China—and ensuring smooth transitions—requires robust legal support to safeguard interests during this transformative period.